Quality

Quality is at the heart of everything we do. It is embedded in every aspect of our business, from processes and procedures to people and ways of working.

At every stage in our manufacturing process the very latest technology is deployed to ensure adherence to specification. This includes:

- XRF analysis and verification of raw material as part of the receipt process

- Robust controls on material traceability, defective material handling, inspection processes and continuous improvement systems.

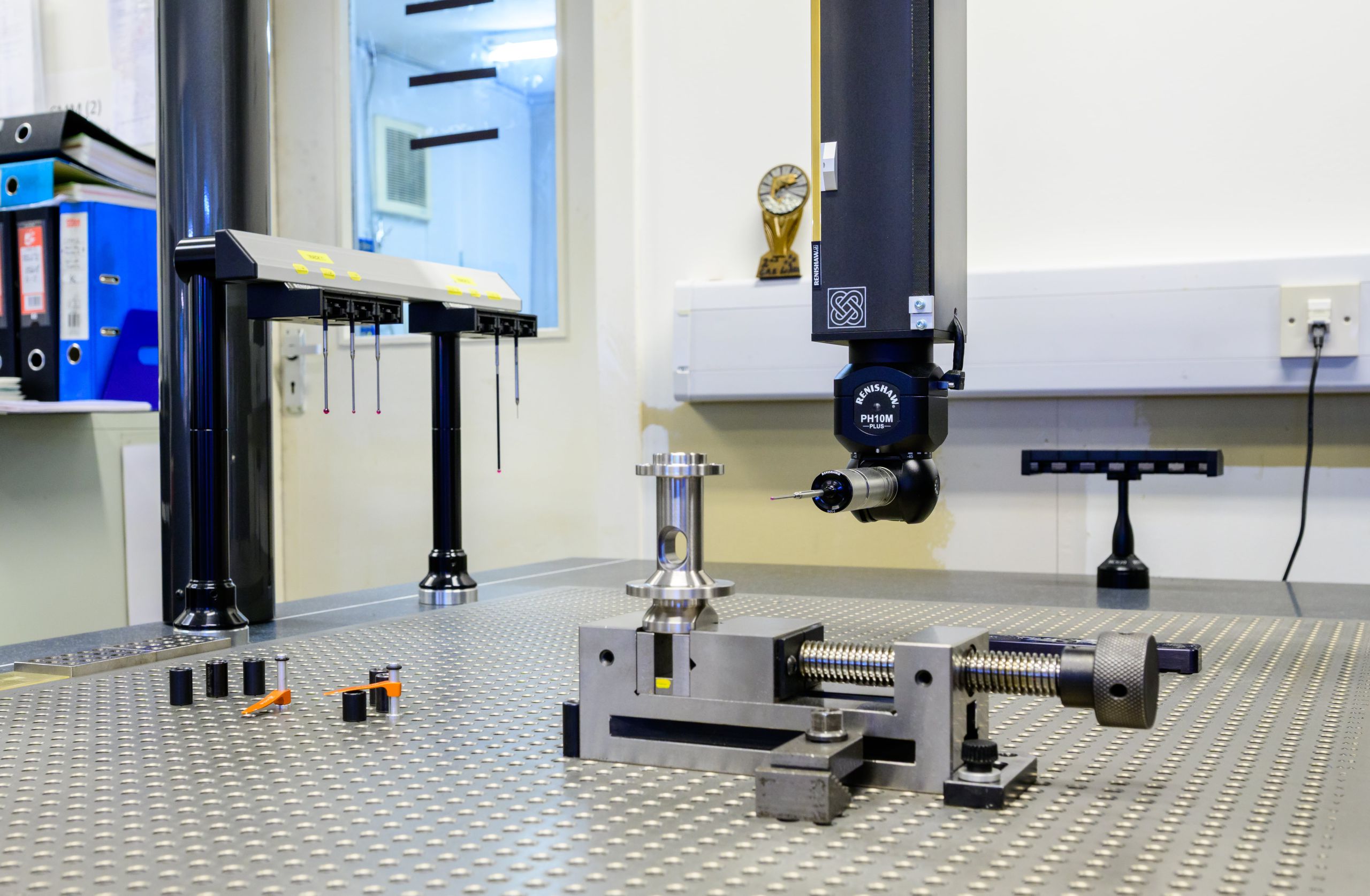

- The use of state of the art probing to do in-process product verification

- The use of fully programmable CMM contact and Optical (Co-ordinate Measuring Machine) to verify parts meet customer specifications.

Our ability to meet a range of quality standards is demonstrated by the National, International, and Customer Specific accreditations which we hold.

Quality Accreditations

Martin Precision are accredited to AS9100D and ISO9001:2015 for the manufacture and supply of CNC precision machines components, including thread rolling, thread validation, non-destructive testing (NDT) and minor assemblies and kittings to customer defined requirements for the aerospace, space and defence including general engineering sectors.

Click logos below to see certificate

Quality Memberships

Click logos below to see certificate

Quality Approvals

Martin Precision’s focus on quality is demonstrated by our outstanding quality score cards achieved with the most prestigious and demanding aerospace companies, and by the National, International, and Customer Specific Approvals which we hold.

Quality Statements

Conflict Minerals Policy

Martin Precision Ltd is fully committed to the responsible sourcing of “Conflict Minerals” tin, tantalum, tungsten and gold, ‘3T&G’.

Martin Precision acknowledges and promotes ‘conflict minerals’ regulations, where relevant, and particularly the provisions of the ‘Dodd-Frank Wall Street Reform and Consumer Protection Act (2010)’ and of applicable European regulations.

Martin Precision expects its suppliers to support its efforts and to take steps to ensure that 3T&G that have funded armed groups are not used in materials supplied to Martin Precision.

Martin Precision is actively engaging with suppliers that provide materials that may contain 3T&G and requiring their cooperation to see that the necessary due diligence with respect to the source of 3T&G in materials supplied to Martin Precision is conducted.

Martin Precision’s Commitment:

- Fully support the objectives of the U.S. legislation and SEC (U.S. Securities and Exchange Commission) rules on the supply of “Conflict Minerals”.

- Not knowingly procure or supply products or materials that contain 3T&G that fund conflict in the Democratic Republic of the Congo (DRC) region.

- Require our supply base to perform due diligence to see that they are using only those sources of 3T&G that are certified as “Conflict Free”.

- Require our approved supply base to provide written evidence documenting that the materials used in products or materials supplied to us are “Conflict Free”.

Martin Precision’s Expectations of Approved Suppliers:

- Supply “Conflict Free” material, i.e any 3T&G necessary to the functionality or production of supplied materials must not directly or indirectly fund armed groups in the DRC or adjoining countries.

- Adopt conflict minerals policies. Suppliers must adopt a policy regarding conflict minerals that facilitates compliance with Martin Precision’s policies, implement management systems to support compliance with these policies and require their suppliers to take the same steps.

- Collect information from their suppliers regarding the source of any 3T&G in supplied materials and cooperate with Martin Precision and Martin Precision customer inquiries regarding conflict minerals in supplied materials. Suppliers must pass down conflict minerals inquiries to the smelter level.

If our suppliers are providing non-conflict free material, Martin Precision will immediately change to a “Conflict Free” approved source.

Modern Slavery Statement

In 2015 the UK Government passed the Modern Slavery Act as part of a wider effort to combat Human Rights abuses across the globe. Modern slavery is a crime and a violation of

fundamental human rights. It takes various forms, such as slavery, servitude, forced and

compulsory labour and human trafficking, all of which have in common the deprivation of a

person’s liberty by another to exploit them for personal or commercial gain.

These three statements are made pursuant to section 54(1) of the Modern Slavery Act 2015 and are made on behalf of Martin Precision Ltd.

- Martin Precision has a zero-tolerance approach to any form of modern slavery.

- Martin Precision is committed to acting ethically in all our business dealings and relationships and establishing effective systems and controls to safeguard against any form of modern slavery in our supply chain.

- Martin Precision and our employees do not engage in practices and do not infringe applicable laws and regulations relating to slavery, human trafficking, forced labour and child labour; and we shall take all reasonable measures to ensure that our suppliers and other entities acting on our behalf do not engage in practices or infringe applicable laws and regulations relating to slavery, human trafficking, forced labour and child labour.

REACH

Martin Aerospace Ltd is working in accordance with the EU REACH legislative requirements. This requires our suppliers to notify Martin Precision of their compliance.

Registration, Evaluation, Authorisation and restriction of Chemicals EC No. 1907/2006. (REACH) (As Amended) http://echa.europa.eu/web/guest/home

REACH (Registration, Evaluation, Authorisation and restriction of Chemical substances) is the EU regulation for safe chemical use that entered into force on 1st June 2007. Its main aims are “to improve the protection of human health and the environment from the risks of chemicals while enhancing the competitiveness of the EU chemicals industry”. In the UK, the authority with responsibility for REACH is the Health and Safety Executive (HSE).

These obligations, summarised below, affect everyone in the Martin Precision supply chain, from importers and manufacturers through to the final point of sale

- Suppliers of articles containing substances on the Candidate List in a concentration above 0.1% w/w have to provide sufficient information to ensure safe use of the article including, as a minimum, the name of the substance.

- Suppliers of substances on the Candidate List must provide a Safety Data Sheet (SDS)

- Suppliers of preparations not classified as dangerous must provide a SDS upon request if the preparation contains a listed substance above 0.1% w/w (0.2% w/w for gaseous preparations).

Get in touch to discuss your next project